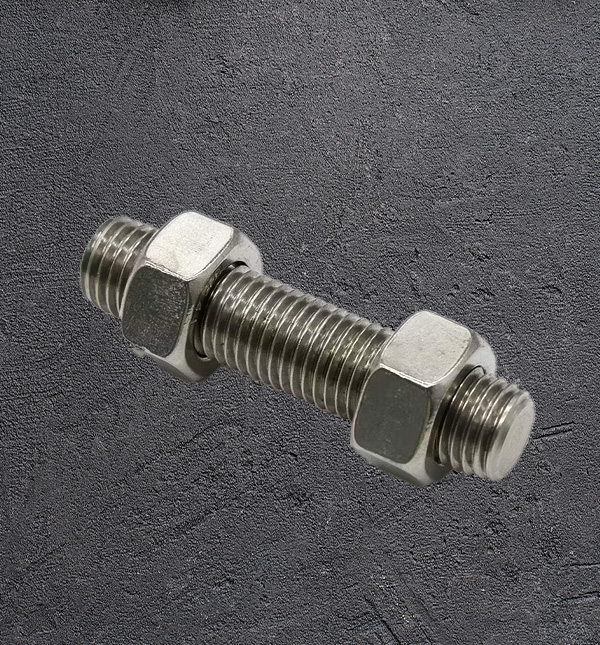

STUD BOLTS

Stud bolts are essential fastening components commonly used in heavy-duty industrial applications where secure and durable connections are critical. Unlike traditional bolts, which have a head on one end and a threaded shaft on the other, stud bolts feature threads on both ends, allowing them to be used in a variety of configurations for securing flanges, pipes, valves, and other equipment. Their design makes them ideal for use in high-pressure and high-temperature environments, such as those found in industries like oil and gas, chemical processing, power generation, and construction.

Materials Commonly Used to Make Stud Bolts

Stud bolts are made from a variety of materials depending on the requirements of the application, such as strength, corrosion resistance, temperature resistance, and environmental conditions. Below are some of the most common materials used in the manufacturing of stud bolts:

1. Carbon Steel

- Properties: Carbon steel stud bolts are strong, durable, and cost-effective, making them suitable for general-purpose applications. They are often used in environments that do not involve exposure to extreme temperatures or corrosive chemicals.

- Applications: Used in construction, machinery, automotive, and non corrosive environments.

2. Stainless Steel

- Properties: Stainless steel stud bolts o er excellent corrosion resistance, making them ideal for use in environments where moisture, chemicals, or harsh conditions are present. They are available in grades such as 304 and 316, with 316 being more resistant to corrosive substances.

- Applications: Commonly used in food processing, chemical plants, marine applications, and o shore industries.

3. Alloy Steel

- Properties: Alloy steel stud bolts are made by alloying carbon steel with other elements such as chromium, molybdenum, or nickel. This enhances their strength, toughness, and resistance to wear and high temperatures.

- Applications: Ideal for high-pressure, high-temperature applications, including the oil and gas industry, power plants, and aerospace.

4. Monel

- Properties: Monel is a nickel-copper alloy known for its exceptional resistance to corrosion, especially in seawater or acidic environments. It is also very strong and can withstand high temperatures.

- Applications: Used in marine, chemical processing, and marine-based industries where resistance to saltwater and chemicals is needed.

5. Inconel

- Properties: Inconel is a high-strength, high-temperature-resistant alloy based on nickel and chromium. It is extremely resistant to oxidation and corrosion, even in very high temperatures (up to 1,000°F or higher).

- Applications: Ideal for use in aerospace, power generation, and chemical processing where extreme conditions are encountered.

6. Titanium

- Properties: Titanium stud bolts are lightweight, strong, and highly resistant to corrosion, especially in harsh chemical environments and at elevated temperatures. Titanium has excellent strength-to-weight ratio and is highly resistant to oxidation.

- Applications: Used in aerospace, medical, and chemical industries, particularly in applications requiring low weight and high performance.

7. Brass

- Properties: Brass stud bolts are highly resistant to corrosion, particularly in marine and humid environments. They are softer than steel but provide good resistance to oxidation and wear.

- Applications: Used in plumbing, electrical applications, and environments where low corrosion and good thermal conductivity are required.

8. Copper

- Properties: Copper stud bolts have excellent electrical and thermal conductivity, corrosion resistance, and are non-magnetic. However, they are not as strong as other metals like steel.

- Applications: Primarily used in electrical applications or where high conductivity is required.

Each of these materials provides specific benefits depending on the application, ensuring that stud bolts perform well under the required conditions, whether it’s high temperatures, corrosive chemicals, or extreme mechanical stress.

The threaded design allows for easy installation and removal, as they can be installed through the flange and tightened with nuts on both sides, providing a reliable and even clamp load. Stud bolts are available in various sizes, lengths, and thread configurations to

suit specific application requirements.

In industries where maintenance, repair, and system disassembly are common, stud bolts o er a versatile and reliable fastening solution. Their ability to maintain a strong connection under extreme pressures and temperatures ensures the safety and integrity of critical systems.

Key Features:

- Dual-Thread Design for Easy Installation

- High Strength and Durability

- Resistance to High-Pressure and High-Temperature Conditions

- Corrosion-Resistant Materials

- Versatile Applications in Heavy-Duty Industries

Stud bolts are essential for ensuring secure, leak-free connections in critical applications, providing the strength, flexibility, and reliability needed for the safe operation of industrial systems and machinery.