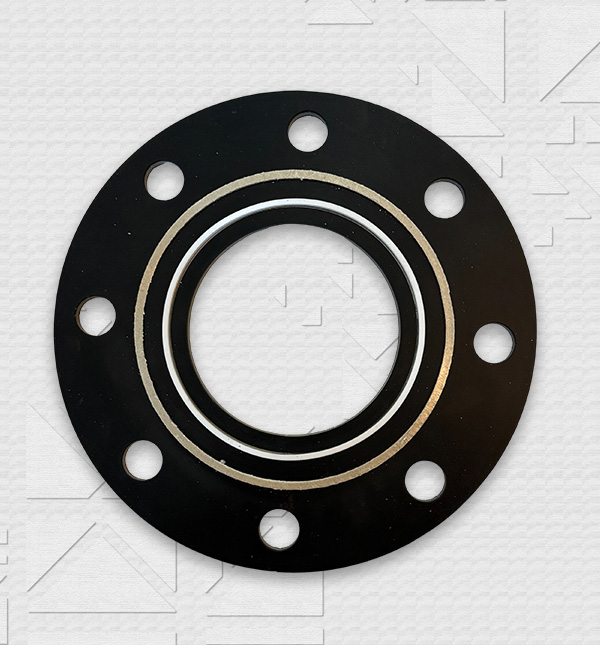

FLANGE INSULATION KITS

Flange Insulation Kits are essential sealing solutions designed to prevent galvanic corrosion and minimize electrical conductivity between flanged connections in pipelines, valves, and other critical systems. These kits are commonly used in industries such as oil and gas, petrochemical, and water treatment, where the integrity of the equipment and the safety of operations depend on maintaining proper insulation at flange joints.

A Flange Insulation Kit typically includes various components such as insulating gaskets, washers, sleeves, and bolts, all of which work together to electrically isolate flanged joints. This isolation helps to prevent the flow of stray electrical currents, which could otherwise cause corrosion or degradation of the metal components. The insulating materials used in these kits are specifically designed to withstand harsh environmental conditions, including extreme temperatures, high pressures, and exposure to aggressive chemicals.

By preventing the electrical connection between di erent metal parts, Flange Insulation Kits help to reduce the risk of corrosion, increase the lifespan of equipment, and ensure the safe and e icient operation of the system. They are particularly important in applications involving cathodic protection systems or where electrical isolation is necessary to avoid interference with sensitive electronic equipment.

Key Features:

- Prevents Galvanic Corrosion

- Reduces Electrical Conductivity Between Flanges

- Enhances Equipment Longevity and Reliability

- Ideal for High-Pressure, High-Temperature Environments

- Compliant with Industry Standards for Safety

Flange Insulation Kits are a crucial component for maintaining the integrity of pipeline systems and other flanged connections, ensuring that operations run smoothly and safely by preventing corrosion and electrical interference in critical industrial systems.