SOFT CUT GASKETS

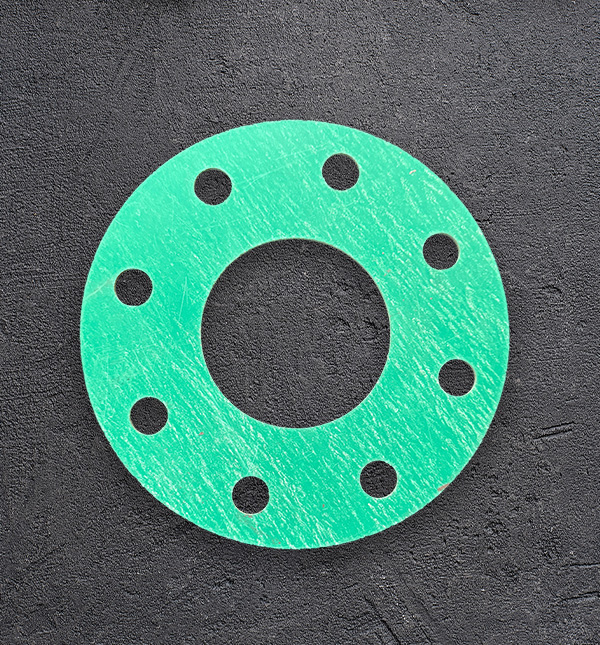

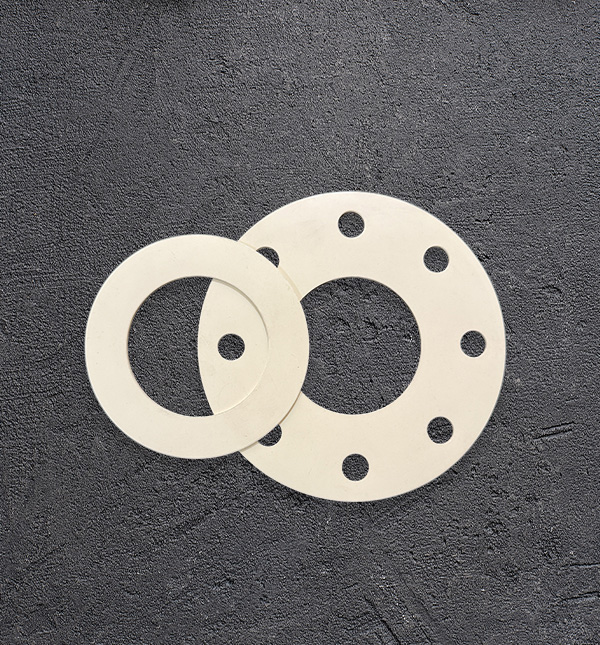

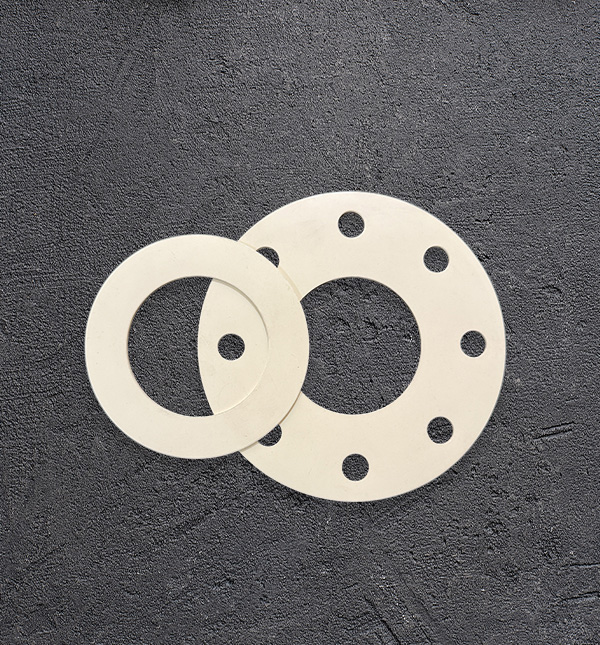

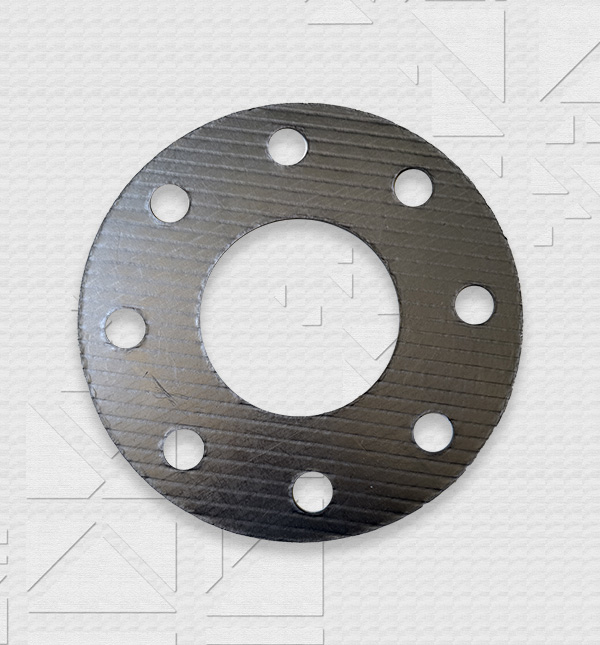

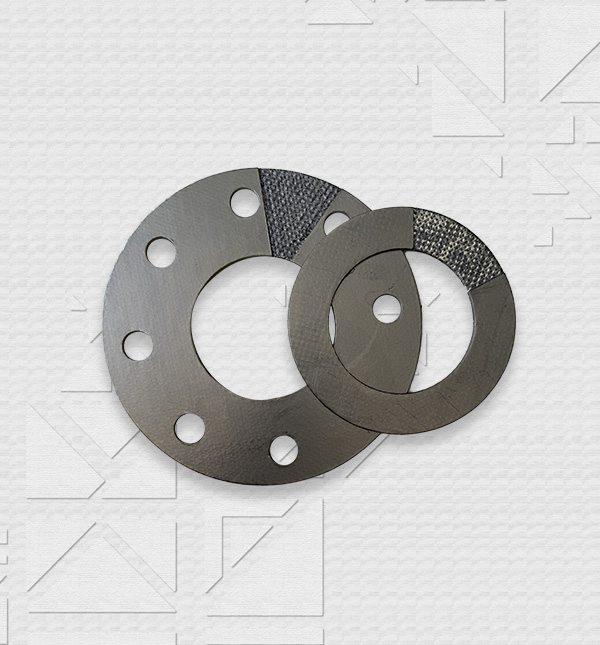

CNAF -NON ASBESTOS

CNAF (Compressed Non-Asbestos Fiber) Gaskets are high-performance sealing solutions designed to provide reliable, durable, and e icient seals in a variety of industrial applications. These gaskets are made from a blend of non-asbestos fibers, fillers, and binding agents, o ering an excellent alternative to traditional asbestos-based gaskets. CNAF gaskets are specifically engineered to provide exceptional sealing properties in high temperature, high-pressure, and corrosive environments while ensuring safety and environmental compliance.

Ring Joint Gaskets feature a distinctive, circular, and beveled design that allows them to create a strong, leak-proof seal when compressed between two flanges. The unique shape ensures that the gasket conforms to the flange surface and maintains a high level of sealing integrity under extreme conditions, preventing fluid or gas leaks.

The composition of CNAF gaskets includes fibers such as aramid, carbon, or glass, which are combined with fillers like graphite or PTFE (polytetrafluoroethylene). This combination results in a gasket that is not only strong and resilient but also highly resistant to thermal cycling, chemicals, and physical wear. CNAF gaskets are designed to maintain their sealing ability even in extreme conditions, making them ideal for use in industries like oil and gas, chemical processing, power generation, and manufacturing.

CNAF gaskets provide a non-toxic and environmentally friendly solution, as they do not contain asbestos, which is hazardous to health. They are available in a wide range of sizes, thicknesses, and configurations, allowing them to be customized to meet the specific needs of di erent applications, including flange seals, valve seals, and pipe joints.

Key Features:

- Non-Asbestos and Environmentally Safe

- High-Temperature and Pressure Resistance

- Excellent Chemical Resistance

- Durable and Long-Lasting Performance

- Flexible and Customizable for Various Applications

CNAF gaskets are a trusted choice for industries requiring reliable, safe, and durable sealing solutions. Their performance, combined with the absence of asbestos, ensures both e ective sealing and a safer working environment for industrial operations.

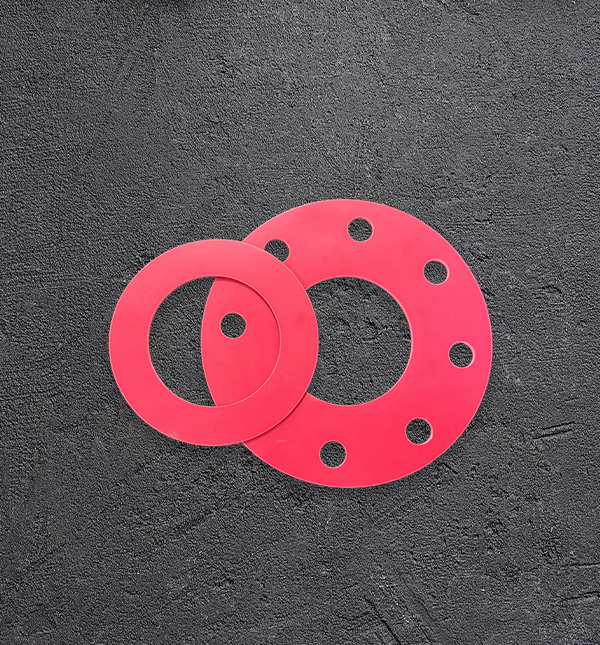

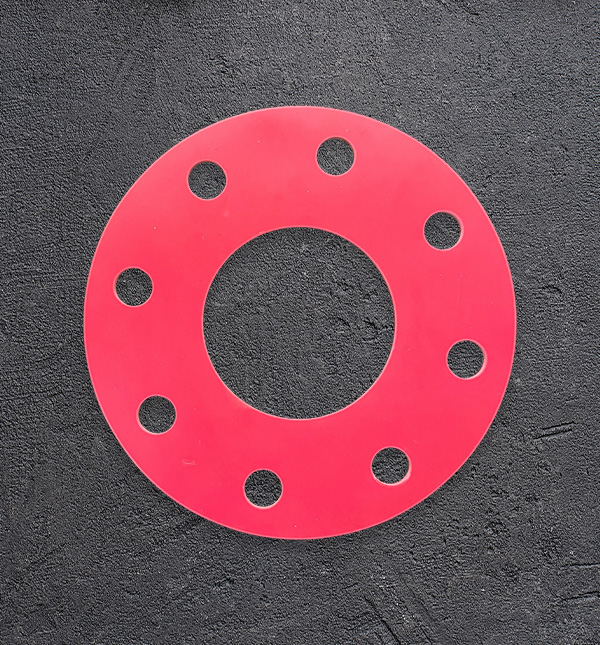

RUBBER GASKETS

Rubber gaskets are versatile, cost-e ective, and reliable sealing solutions widely used across a variety of industries. Made from synthetic or natural rubber materials, these gaskets are designed to provide a flexible, durable, and leak-proof seal between two surfaces, preventing the escape of gases, liquids, or contaminants. Their ability to withstand a range of environmental conditions, including vibration, temperature fluctuations, and chemical exposure, makes rubber gaskets an essential component in industries such as automotive, food processing, plumbing, and HVAC systems.

Rubber gaskets are available in a variety of rubber compounds, including:

- NEOPRENE

- EPDM

- NITRILE

- VITON

- SILICONE

- HYPALON

each tailored to provide specific properties such as oil resistance, heat resistance, flexibility, or ozone resistance. These materials allow rubber gaskets to perform well in sealing applications where other materials may not be as e ective. The soft, compressible nature of rubber enables it to create tight seals, even on uneven or irregular surfaces, ensuring leak prevention and reliable performance.

Key Features:

- Excellent Flexibility and Compression Set Resistance

- Wide Range of Material Options for Di erent Applications

- High Resistance to Vibration and Movement

- Effective Sealing Performance in Various Temperatures

- Cost-Effective and Easy to Customize

Rubber gaskets are a dependable sealing choice for industries requiring an effective, economical, and versatile solution to prevent leakage and ensure operational e iciency. Whether sealing a small component or large industrial system, rubber gaskets deliver consistent, long-lasting performance across a broad range of demanding environments.

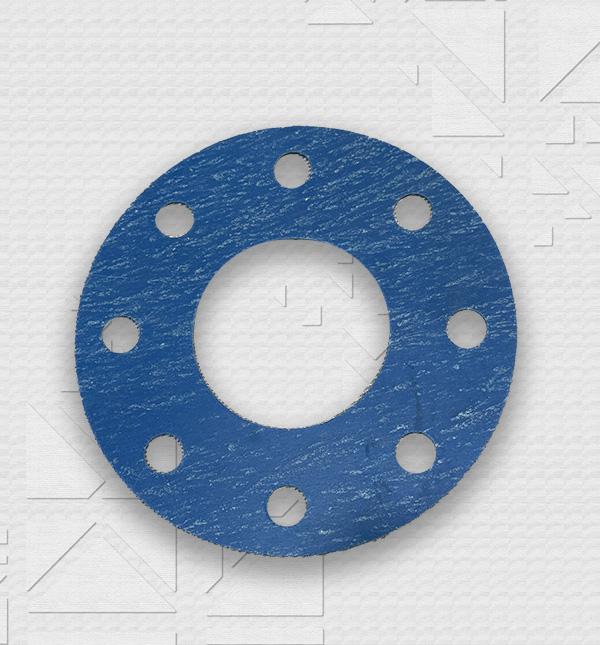

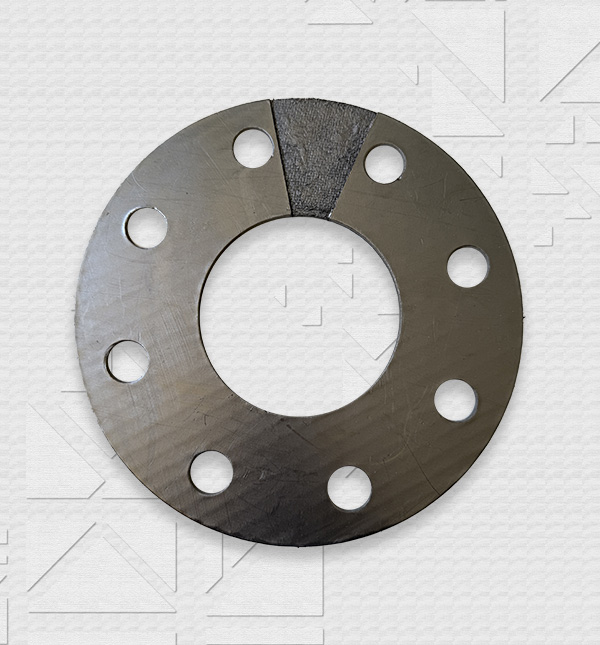

GRAPHITE GASKETS

Graphite gaskets are high-performance sealing solutions widely recognized for their exceptional thermal stability, chemical resistance, and flexibility. Made from pure or expanded graphite, these gaskets are ideal for sealing high-temperature, high-pressure, and aggressive chemical environments. Graphite gaskets are commonly used in industries such as chemical processing, power generation, oil and gas, and aerospace, where reliable sealing is critical for safety and operational efficiency.

Graphite itself is a naturally soft, flexible material that, when used in gasket form, offers excellent sealing properties. The material can conform to uneven surfaces and effectively seal under extreme pressure and temperature conditions. Expanded graphite gaskets, in

particular, are created by processing natural graphite to increase its volume and flexibility, making them even more adaptable and resilient.

Major Types are:

- PURE GRAPHITE

- GRAPHITE WITH STEEL FOIL REINFORCED

- GRAPHITE WITH STAINLESS STEEL TANGED INSERT

- GRAPHITE WITH WIRE REINFORCED

Key Features:

- High-Temperature and High-Pressure Resistance

- Excellent Chemical Resistance

- Superior Leak Prevention

- Flexibility and Conformability to Uneven Surfaces

- Environmentally Safe and Non-Toxic

Graphite gaskets are highly valued for their ability to withstand harsh conditions and provide long-lasting, leak-proof performance. Whether in critical sealing applications or general-purpose use, graphite gaskets are a trusted choice for industries demanding durable, e ective, and safe sealing solutions.

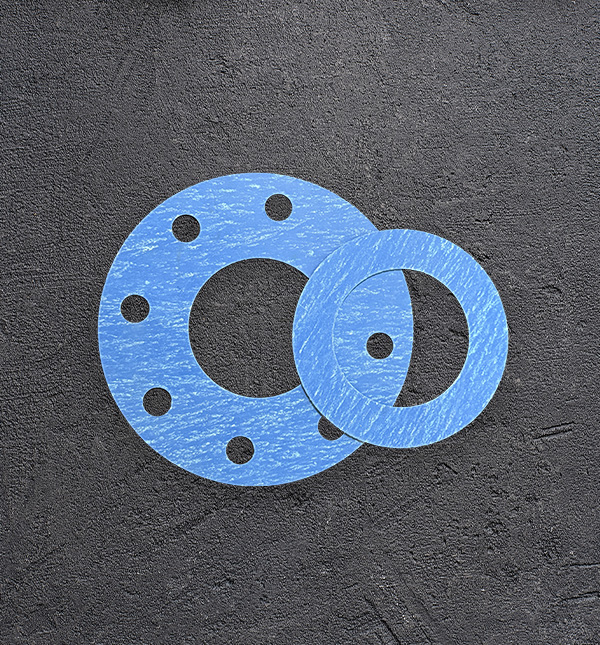

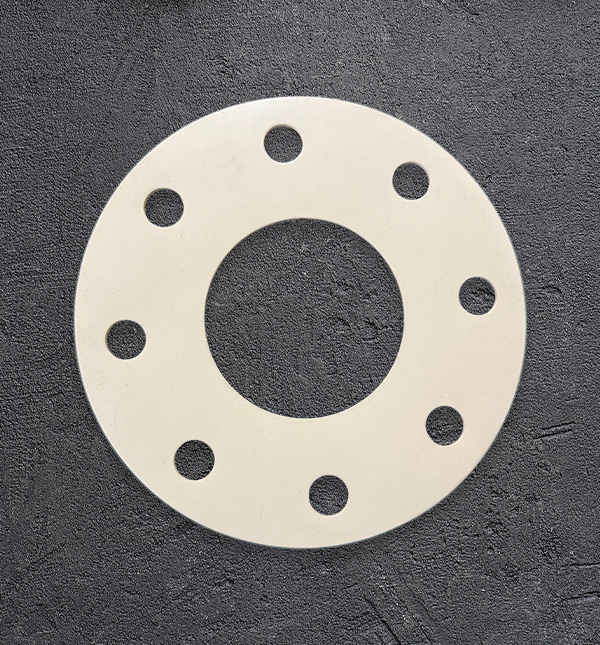

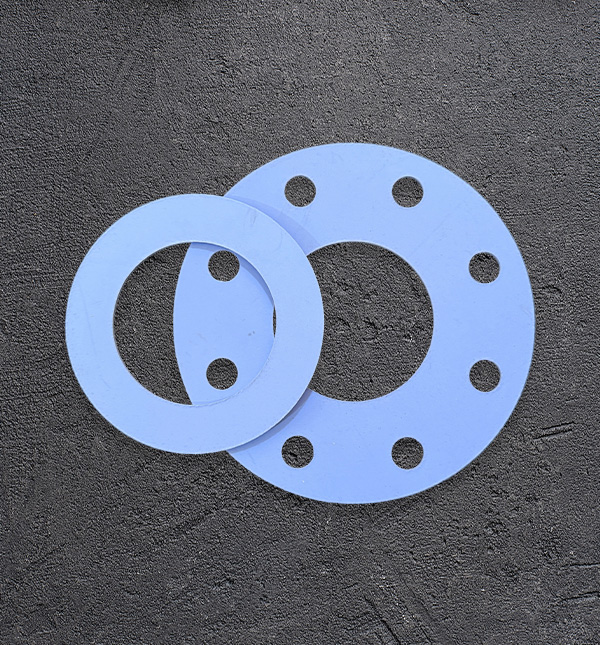

PTFE GASKETS

PTFE (Polytetrafluoroethylene) gaskets are high-performance sealing solutions known for their outstanding chemical resistance, high-temperature stability, and non-reactive properties. Made from a synthetic fluoropolymer, PTFE gaskets are commonly used in industries such as chemical processing, pharmaceuticals, food and beverage, and petrochemical, where leak-proof seals are essential in aggressive and demanding environments.

PTFE gaskets are available in various forms, including:

- VIRGIN PTFE

- EXPANDED PTFE

- GLASS FILLED PTFE

- SILICA FILLED PTFE

- BARIUM SULPHATE FILLED PTFE

- CARBON FILLED PTFE

each offering unique advantages for di erent sealing applications. Expanded PTFE, for example, is softer and more flexible, making it an ideal choice for sealing irregular or rough flange surfaces.

Key Features:

- Exceptional Chemical and Corrosion Resistance

- High-Temperature Stability

- Non-Reactive and Non-Toxic

- Low Friction and Non-Stick Properties

- Wide Range of Applications in Harsh Environments

- CARBON FILLED PTFE

PTFE gaskets are an excellent choice for industries requiring a reliable, durable, and safe sealing solution in challenging environments. Their chemical resistance, high-temperature performance, and non-reactivity make them a go-to option for preventing leaks and ensuring system integrity in critical industrial processes.